. Villa Belgica

- Bank

- Reconstruction

- Conservation

- Adding of storeys

Standing on Avenue de Grande-Bretagne, Villa Belgica is UBS’ Monaco head office. Built in the 19th century, it is now getting a facelift and is under renovation. UBS Bank wants to add storeys to the villa while retaining its historic façades built in 1899 on four levels. The current building has already been raised in height twice:

- 1930: raised with a third floor

- 1959: raised with a fourth, fifth and sixth floor

The final project will be an eleven-storey building with two basement levels containing offices and reception areas for UBS clients. The project will last 28 months. This highly aspirational project is based on the desire to provide optimal comfort in summer without air conditioning, by natural ventilation, but also a low-carbon design based on re-use of the materials and the use of local bio-sourced materials.

The project will eventually be awarded two environmental certifications:

- BREEAM – Excellent Level

- BD2M (Sustainable Mediterranean Buildings of Monaco) – Gold Level

Project details:

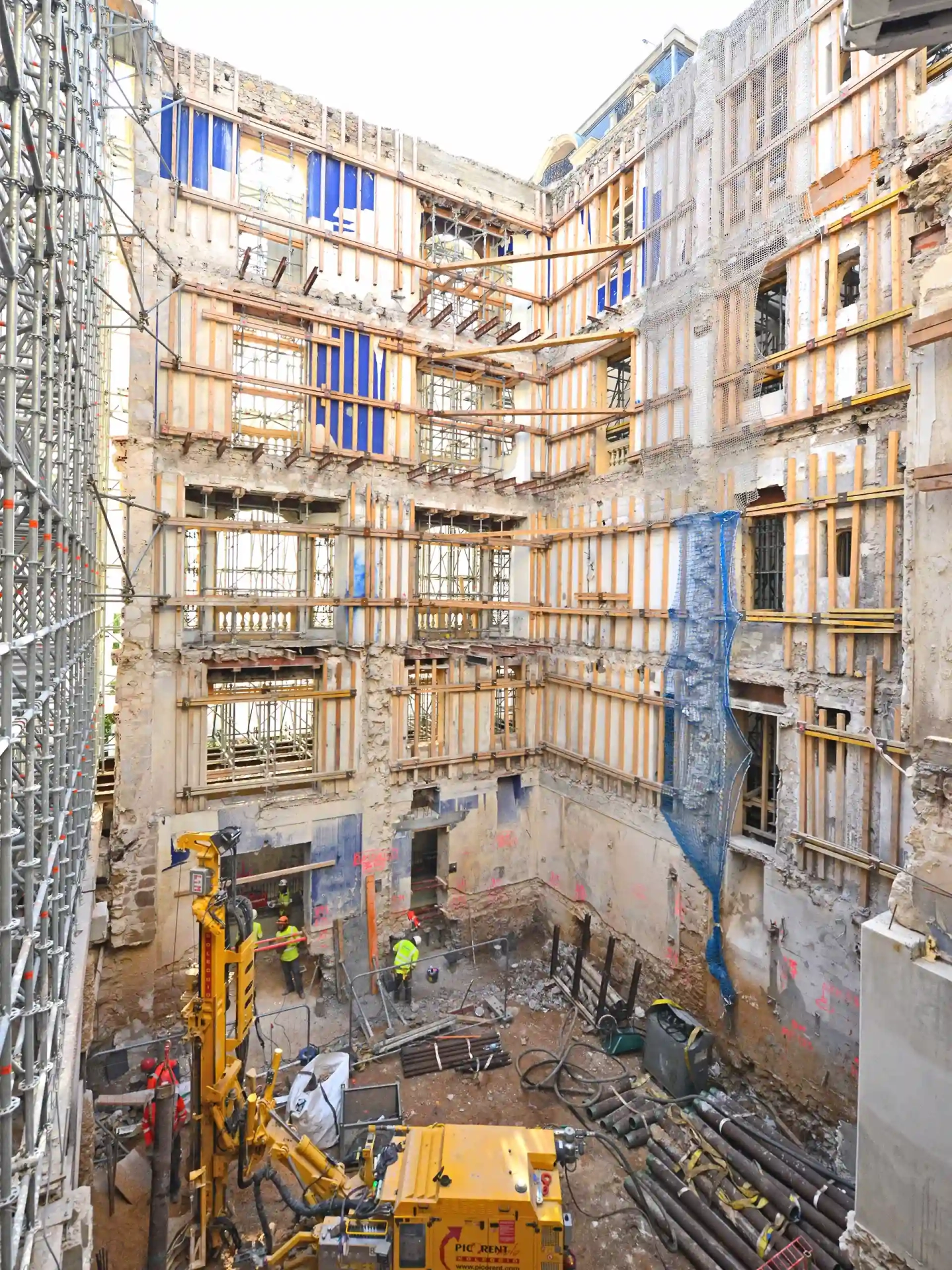

Retaining of façades: One of the features of this project is that three out of the four façades of the initial building are to be retained. While the top 3 floors will be demolished in their entirety, only the north-east façade will be demolished on the lower levels. The retained façades must be reinforced to withstand the horizontal stresses, such as wind. To achieve this, façade reinforcement has been implemented.

Underpinning of retained façades: Underpinning is a system that involves making structural modifications to the existing structure. On the UBS project, this work method has been used to create foundations under the retained façades. The foundation system selected is a series of micropiles sunk all around the building's façades. In addition to this, threaded footings are built underneath the existing façades. As it was not possible to create all the footings at once, they were created in 1.5 to 2 metre increments.

Use of prefabrication: The central element of the UBS project, the stairwell is made up of two rows of curved walls, between which the flights of stairs are placed.

For these elements, the prefabrication was done:

In the factory for the curved walls of the central core. Moulds were made to measure, allowing the interior and exterior curved walls to be produced in the workshop.

On site for the flights of stairs. Using a steel mould made to measure for the project and transported to the site, the flights of stairs are produced in the project's logistics area before being installed directly on site.

This use of prefabrication means that the highest levels of finish can be achieved while limiting the production of waste, which is in line with the project's environmental objectives.

The initial demolition phase took place between January and September 2022, after the façades had been reinforced with external scaffolding.

The second phase of foundation by underpinning went on until December 2022, enabling the shell to be raised from B2 to the 11th floor, the point reached today. *B = BASEMENT

These operations were carried out with the utmost care by our site staff supervised by our site manager, which was done meeting the tightest of schedules.

The second phase of the project has been ongoing since the beginning of July, with a final target date of october 2024.

Si vous ne parvenez pas à scanner le QR code.

- Partial demolition of 3 floors

- Reconstruction and adding of storeys from the 5th to the 11th floor

- 2 basement levels

- Retaining of 3 of the 4 façades

- Underpinning of retained façades

The project in pictures

Download